DRY SUCTION

EXCAVATION

GENERAL INFORMATION

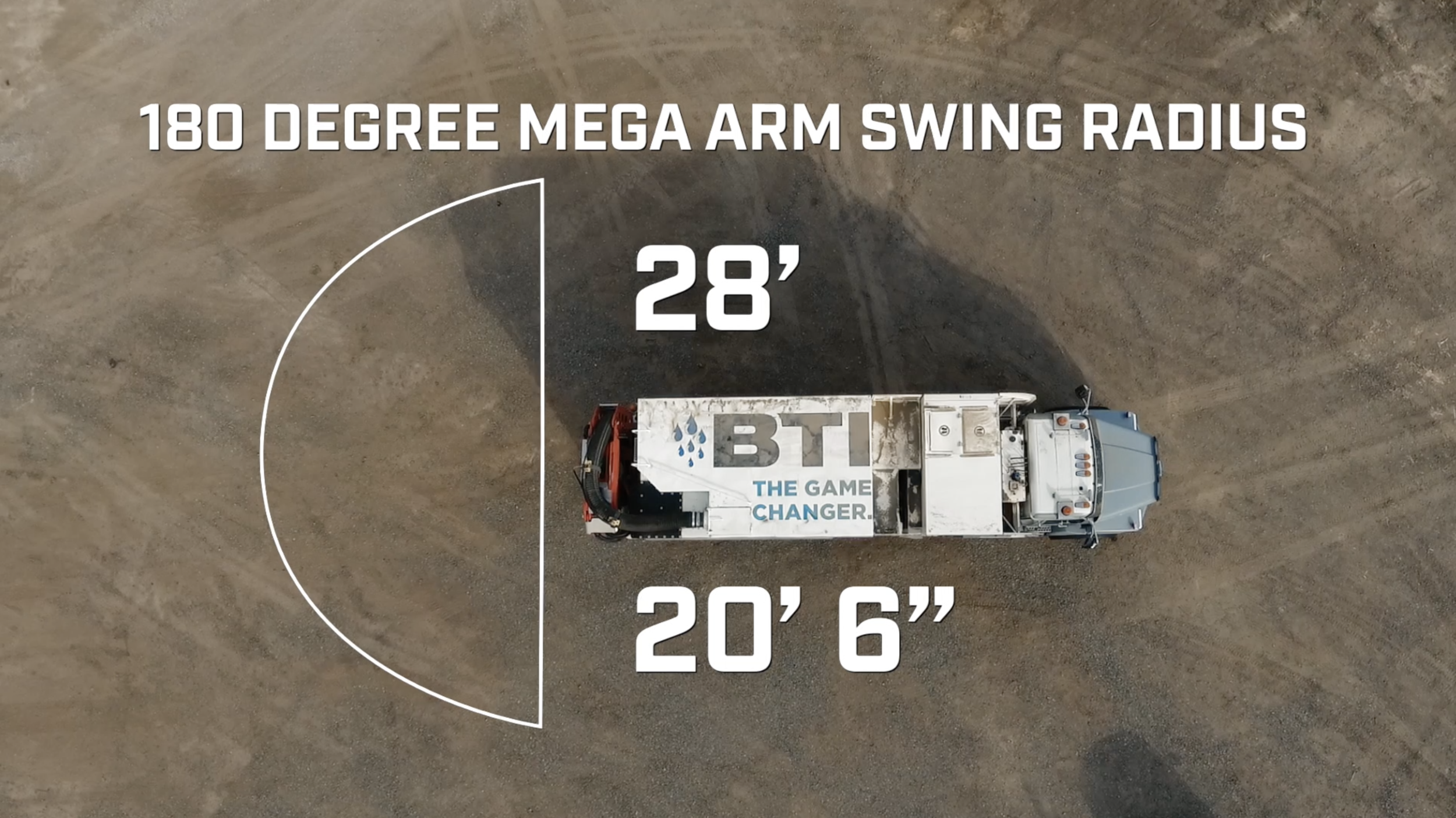

BTI owns and operates the first dry, suction excavation units in the United States, the Dino. Suction excavation provides a safer, low risk alternative to traditional excavation techniques. The Dino’s high suction powered truck expertly lifts away ground, with little risk of damage to existing facilities or personal injury. The Dino operates using two powerful fans that generate 24,000 CFM for excavation, uses a 20’ articulated excavator style boom with a 10” suction hose, air lance and can hold up to 10 yards of DRY REUSEABLE material. It executes precision excavation with complete control using the remote controlled power arm/boom. The resulting excavated spoils are dry and can be unloaded at the project site either on the ground for reuse or directly into a 20CY bin for containment.

The unit can safely remove soil around underground utilities. The precision, no-dig approach, eliminates almost all risk regarding strikes to service lines and underground utilities.

The Dino is unbeatable in terms of underground utility non-destructive, precision excavation, highly productive, cost efficient excavations.

Check out the DINO in the MBE Magazine Spring 2018 Edition

DRY SUCTION EXCAVATION SPECS

ADVANTAGES

New technology and new equipment designed and built to excavate using air. This is not retrofitted or adapted old technology.

By using air and suction excavation, the Dino can probe for and daylight utilities safer and quicker than a backhoe and hand digging. Underground utilities can be exposed from all sides quickly and safely.

No water is introduced into the operations as in hydrovac operations. The Dino unit keeps excavations dry with no water build up or muddy operations. Field personnel are able to review soil types and staining indicators under dry conditions.

The by-product material is DRY & immediately REUSABLE on-site.

The Dino unit is efficient and effective as it stays on-site for the entire day with continuous operations.

Comparable units creates wet, un-useable material that require secondary handling and additional costs due to the use of water for excavation. These units also have less productive time on-site each day because they leave the site to unload the mud slurry they’ve created.